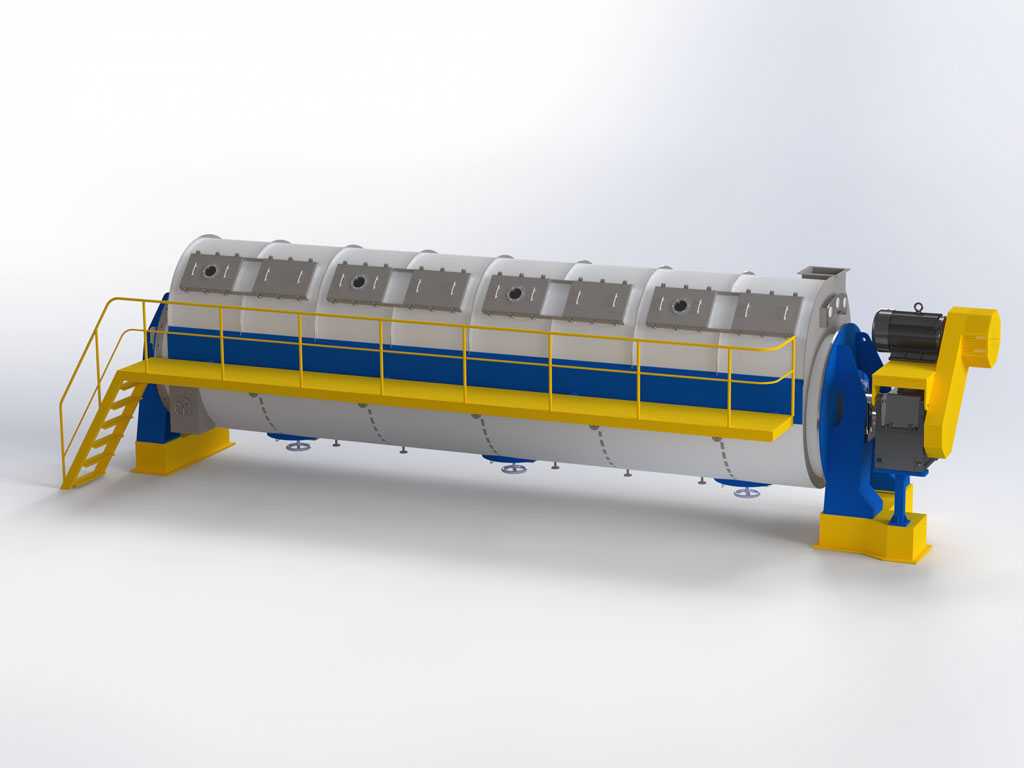

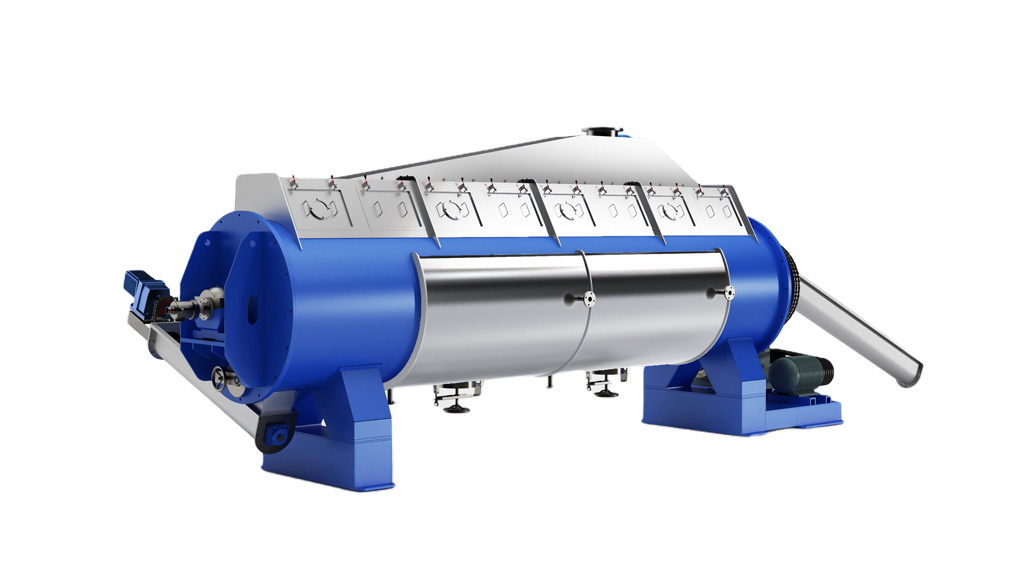

Fishmeal dryer is a kind of equipment that obtains fishmeal by drying the solids after cooking in fishmeal production by using steam as a heat source. Fishmeal dryers generally consist of a rotating main shaft and a stationary shell. The fishmeal dryer is the most important fishmeal equipment in the fishmeal processing. The processing performance of the dryer directly affects the quality of the final fishmeal.

1.What is a steam wet fishmeal dryer

First of all, the processing technology of fish meal is generally divided into ordinary direct fire drying and low temperature steam drying process, so our steam wet fish meal dryer is generally used in low temperature steam drying process.

Rapid low temperature drying process (two-stage drying method):

The first stage is steam drying. Since the steam system operates under low pressure, its operating temperature is 30°C lower than that of the so-called dryer, which is very effective in maintaining the high digestibility of fishmeal.

In the second stage, the use of indirect hot air drying system can greatly improve the quality of fishmeal.

2.The working principle of steam wet fish meal dryer

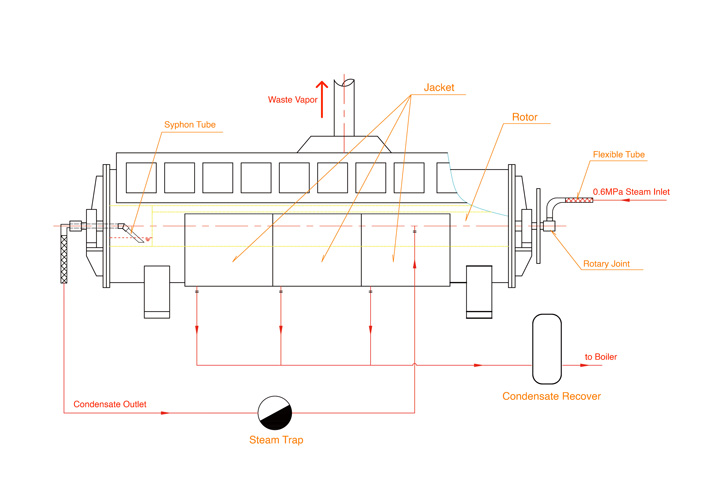

FM series steam wet fish meal dryer adopts saturated steam as heat source (rated steam pressure 0.6MPa), which belongs to indirect steam dryer. It is mainly heated by the main shaft, and can also be heated through the interlayer of the outer casing. The spindle speed is slow, usually 10 to 12 rpm. The material is slowly transferred from the feed end to the discharge end through the pusher system on the outer edge of the blade. The discharge is controlled by a speed-adjustable screw conveyor, which is convenient to adjust the size and speed of the discharge according to the needs.

The heating blades are installed on high-quality seamless steel pipes, and combined with an efficient condensate drainage system, the heating area of the blades can be utilized to the maximum efficiency and a good heat exchange efficiency can be maintained. A stainless steel scraper is installed between the heating blades, which can stir the material, prevent the material from being piled up between the blades, and ensure the complete evaporation of water. The water vapor passes through the stainless steel air collecting hood at the top of the dryer, and is continuously discharged from the machine under the action of the induced draft fan.

3. Application of steam wet fishmeal dryer in other industries

Due to the unique structural design and excellent drying effect of the fish meal dryer, the dryer can also be widely used in the drying of powdery and granular materials in the food, chemical, pharmaceutical, building materials and other industries.

The products that have used this series of dryers are: starch, glucose, fish meal, granulated sugar, sugar, wine tank, feed, gluten, plastic resin, coal powder, dye, etc.

Feeds Machinery provides the design, manufacture, installation, commissioning and after-sales maintenance of a complete set of fishmeal and fish oil equipment production lines, and provides customers with complete sewage and waste gas treatment solutions to achieve pollution-free fishmeal industry.

Based on years of R&D and production experience of fishmeal equipment production lines, Feeds Machinery has launched the Fishmeal Process (FMP), a wet-process fishmeal production process, which is suitable for the production of fishmeal with a raw material capacity of up to 15 tons/hour and above. The produced fishmeal has better quality, high digestibility, low energy consumption and simple operation. If a complete fishmeal and fish oil production and processing system is adopted, the production capacity can be increased by 5% (the digestibility is increased by 3%), and the whole process can be achieved without pollution.