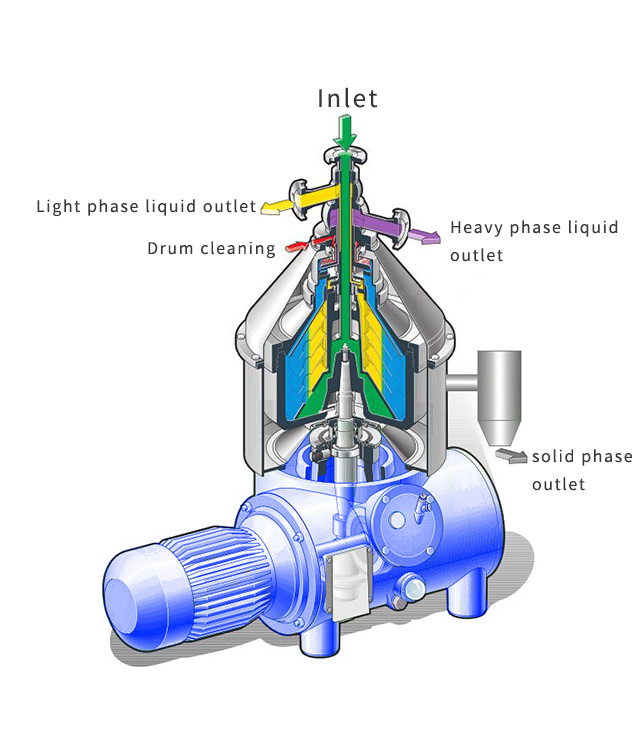

Disc Separator

The disc separator is a mechanical device that continuously separates two liquids or solid-liquid suspensions with different densities by using the principle of centrifugal sedimentation. It has the advantages of high speed, stable operation, all closed inlet and outlet systems, low noise and good separation effect.

Compared with the decanter centrifuge, the rotating speed is higher and the centrifugal effect is better, which is suitable for fish oil refining operations.

Parameters

Core Parameters| Weight | 420-3300(kg) |

|---|---|

| Power | 4-30(kw) |

| Processing Capacity | 500-30000(L/h) |

| Speed | 4800-9600(rpm) |

Features

The separation speed is as high as 7500 rpm, which achieves a good three-phase separation effect, and the quality of the finished fish oil is high.

The adjustment range is wide, the applicability is strong, and it can meet the separation requirements of various raw fish.

Using PLC automatic controller program control, high degree of automation, simple and convenient operation.

The host is made of stainless steel, which has good corrosion resistance.

Application

Vegetable oils: separation and refining operations of soybean oil, rapeseed oil, sunflower oil, cottonseed oil, palm oil, corn oil, peanut oil, rice bran oil, sesame oil, safflower oil, etc.

Animal oils: separation and refining operations of lard, tallow, fish oil, pig blood, chicken blood, etc.

Cold milk separation, hot milk separation, hot milk skim, cheese concentration, goat milk skim, colostrum extraction, casein production.

General fruits and vegetables: apple juice, orange juice, grape juice, etc.

Vegetables: cucumber, spinach, celery, etc.

Tropical fruits: mango, pineapple, passion fruit, etc.

Alcoholic beverages: wine, fruit wine, beer, etc.

Pigment, pepper, tea, loquat leaf, honeysuckle, Shuanghuanglian, Ginkgo biloba, Salvia miltiorrhiza, Banlangen, rutin, Luo Han Guo, rhein, amygdalin, Chinese medicine extraction, etc.

Concentration of microorganisms, separation of extracts (such as penicillin, Escherichia coli, antibiotics, hormones, etc.), extraction of vitamins, concentration and clarification of fermentation broth, separation of animal blood

Separation of PVC, phosphoric acid, hydrogen peroxide, herbicides, pesticides, viscose, catalysts, latex (synthetic), inks and dyes, lubricant additives, cellulose and derivatives, boiler ash, etc.

Waste oil, cutting fluid, quenching fluid, fuel oil, lubricating oil, mixture of oil, water and solid substances to remove moisture, mechanical impurities and clarify and purify.

Methyl ester is washed with water, glycerol is desalted, fatty acid is extracted, methyl ester, glycerol, catalyst, methanol, etc. are separated for transesterification process or separation operation.

Animal bones and internal organs, vegetable stems and leaves, husks and peels, leftovers, waste oil, etc. are separated from oil and water.

Working Principle

After the turbid liquid enters the high-speed rotating drum, it enters the disc stack along the channel, and the multi-components with different densities form three dynamic concentric rings under the action of strong centrifugal force: a small amount of solid particles with high density outward The movement accumulates on the peripheral wall of the drum to form an outer layer; the heavy phase liquid with higher density is thrown to the lower surface of the disc and slides down out of the disc area to form an intermediate layer; the light phase liquid with lower density moves to the center of the drum , forming the inner layer. Then, the three components formed are discharged from the drum through their respective channels.

Document

Get detailed specifications and parameters, Supports on-demand customization, welcome to inquire!