Fast Sludge Drying Low Cost & Consumption

High-efficiency and energy-saving sludge drying process

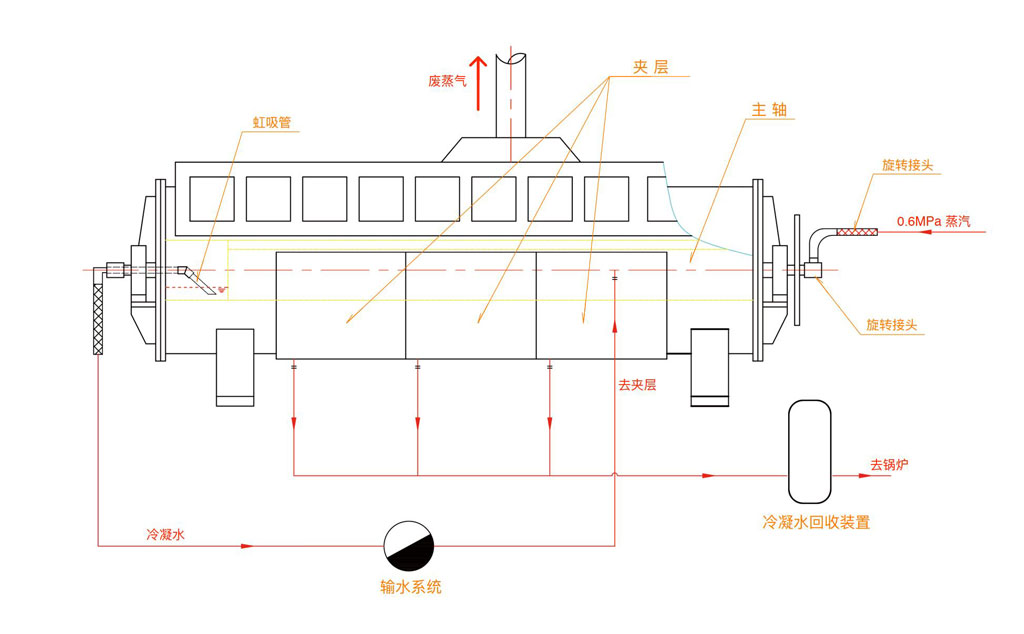

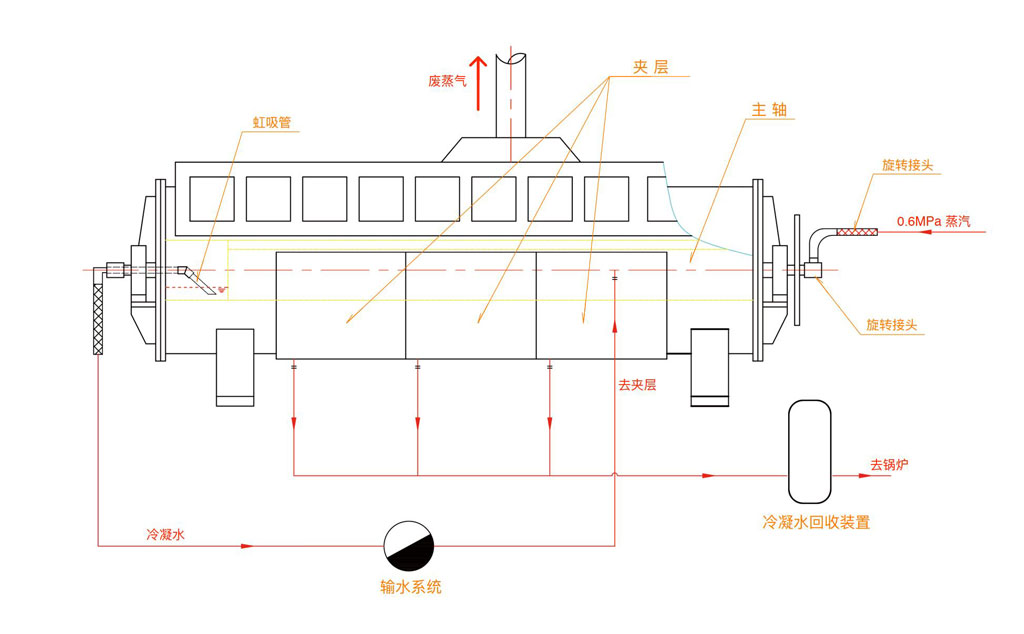

The dryer is a disc sludge dryer, compact design, small footprint, using saturated steam as a heat source, which can achieve lower energy consumption and achieve fast sludge drying operations

Especially suitable for dewatering and drying treatment of various industrial sludge and municipal sludge

Process flow

For Sludge Drying

The complete sludge drying system includes screw conveyor, disc dryer, dust collector, steam condenser and deodorization tower. Wet sludge from screw press sludge dewaterers typically contains 70-80% moisture. The sludge is continuously fed by a screw conveyor into the disc dryer, where it will be heated. The moisture material inside is vaporized and sucked by the blower. The exhaust gas discharged from the dryer enters the steam condenser after dust removal treatment. The condenser turns most of the vapor into condensed water. The exhausted gas will be deodorized by the biological deodorization tower, and then discharged through the chimney. Dry sludge also typically contains 20-30% moisture.

Application Industry

For Sludge drying

The sludge drying process provided by FEEDSMACHINERY can directly dry sewage or sludge with a moisture content of 83% to dry sludge with a moisture content of 10%-30%, with a reduction of up to 90%, low energy consumption, no pollution, and can be widely used in Municipal sludge and industrial sludge (printing and dyeing, papermaking, electroplating, chemical industry, leather, pharmaceuticals, breeding, etc.) are dried and reduced in weight. The dried sludge can be gasified, mixed with burning, composted or building materials and other harmless resources in the later stage. treatment.

Equipment

Core Equipment For Fish Meal Plant

High-efficiency and energy-saving sludge drying process

The dryer is a disc sludge dryer, compact design, small footprint, using saturated steam as a heat source, which can achieve lower energy consumption and achieve fast sludge drying operations

Especially suitable for dewatering and drying treatment of various industrial sludge and municipal sludge

Process flow

For Sludge Drying

The complete sludge drying system includes screw conveyor, disc dryer, dust collector, steam condenser and deodorization tower. Wet sludge from screw press sludge dewaterers typically contains 70-80% moisture. The sludge is continuously fed by a screw conveyor into the disc dryer, where it will be heated. The moisture material inside is vaporized and sucked by the blower. The exhaust gas discharged from the dryer enters the steam condenser after dust removal treatment. The condenser turns most of the vapor into condensed water. The exhausted gas will be deodorized by the biological deodorization tower, and then discharged through the chimney. Dry sludge also typically contains 20-30% moisture.

Application Industry

For Sludge drying

The sludge drying process provided by FEEDSMACHINERY can directly dry sewage or sludge with a moisture content of 83% to dry sludge with a moisture content of 10%-30%, with a reduction of up to 90%, low energy consumption, no pollution, and can be widely used in Municipal sludge and industrial sludge (printing and dyeing, papermaking, electroplating, chemical industry, leather, pharmaceuticals, breeding, etc.) are dried and reduced in weight. The dried sludge can be gasified, mixed with burning, composted or building materials and other harmless resources in the later stage. treatment.

Equipment

Core Equipment For Fish Meal Plant