First order in 2023, a set of 150T fishm...

Disc Dryer

FM series fish meal disc dryer, different from traditional fish meal disc dryer, has a unique spindle design. The main shaft does not expose the welding seam, avoids the welding seam directly contacting the material, and prevents the material from wearing and corroding the welding seam, thus greatly prolonging the service life of the dryer.

The fish meal disc dryer can be manufactured into various sizes and specifications according to the demand of output and under the conditions of transportation. The disc dryer can also be made of carbon steel Q345, stainless steel 304, 316L or bidirectional stainless steel according to the nature of the material.

Features

Seamless steel tube spindle

Adopt seamless steel tube to avoid the risk of spindle breakage

Hidden Seam Design

Reduce the wear of discs and materials and prolong the service life

Stainless Steel Bezel

Prevent the material from slipping in the blade and improve the drying efficiency for fish meal

Application

Raw materials for fishmeal and fish oil processing

Sardines

Anchovies

Basa

Tuna

Miscellaneous Fish

Chicken Claws

Shrimp Shell

Meat and Bone

Most of the world's fish (including freshwater and marine fish) can be used as raw materials for fishmeal processing. Generally, we use raw fish with large catch and relatively low economic value, such as sardines, anchovies and small miscellaneous fish.

In fact, not only fish, the vast majority of fish processing scraps, including shrimp shell heads, tuna steaks, etc., can be processed into high-quality protein powder and fish oil.

Through process adjustment, the fish meal disc dryer can also process the scraps from various meat processing plants, including chicken heads, chicken claws, meat bones, and offal, and turn them into meat bone meal.

By "turning waste into treasure", fish meal disc dryer not only reduces waste discharge, but also creates huge economic benefits for users.

Working Principle

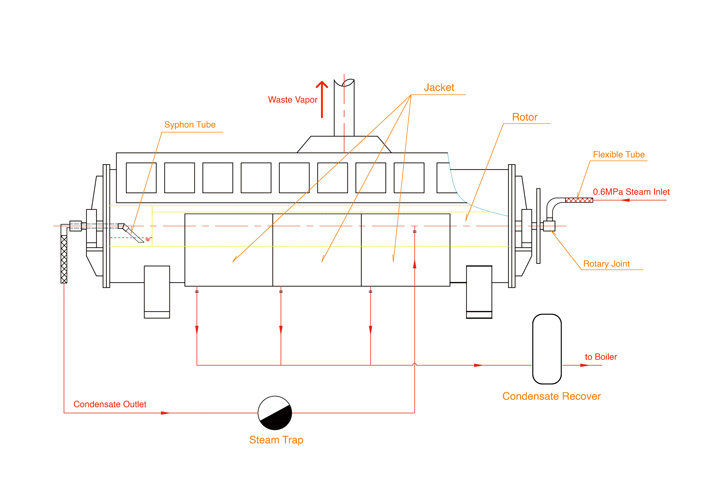

FM series fish meal disc dryer uses saturated steam as heat source (rated steam pressure 0.6MPa), which belongs to indirect steam dryer. It is mainly heated by the main shaft, and can also be heated through the interlayer of the outer casing. The spindle speed is slow, usually 10 to 12 rpm. The material is slowly transferred from the feed end to the discharge end through the pusher system on the outer edge of the blade. The discharge is controlled by a speed-adjustable screw conveyor, which is convenient to adjust the size and speed of the discharge according to the needs.

The heating blades are installed on high-quality seamless steel pipes, and combined with an efficient condensate drainage system, the heating area of the blades can be utilized to the maximum efficiency and a good heat exchange efficiency can be maintained. A stainless steel scraper is installed between the heating blades, which can stir the material, prevent the material from being piled up between the blades, and ensure the complete evaporation of water. The water vapor passes through the stainless steel air collecting hood at the top of the dryer, and is continuously discharged from the machine under the action of the induced draft fan.

Model

| Model | Disc Num | Disc Diameter | Size (mm) | Motor Power (KW) | Heating Area (m2) | Processing Capacity (Mt/24h) |

|---|---|---|---|---|---|---|

| FM-50 | 42 | 1200 | 7600x2000x2850 | 37 | 96 | 50 |

| FM-80 | 45 | 1450 | 8300x2500x3100 | 45 | 158 | 80 |

| FM-100 | 45 | 1450 | 10000x2500x3100 | 55 | 198 | 100 |

| FM-150 | 57 | 1700 | 11200x2500x3200 | 75 | 261 | 150 |

| FM-200 | 59 | 1950 | 11800x3000x3500 | 110 | 350 | 200 |

Material selection according to different raw materials: carbon steel, 304, 316L, double-sided stainless steel, etc.

Cases

Document

Get detailed specifications and parameters, Supports on-demand customization, welcome to inquire!

Related Articles

The price of a complete set of fishmeal ...

How do fish oil refining equipment manuf...

Fishmeal processing machinery is a kind ...

The fish meal dryer is composed of a she...

Fishmeal feed is made of fish and proces...