How do fish oil refining equipment manuf...

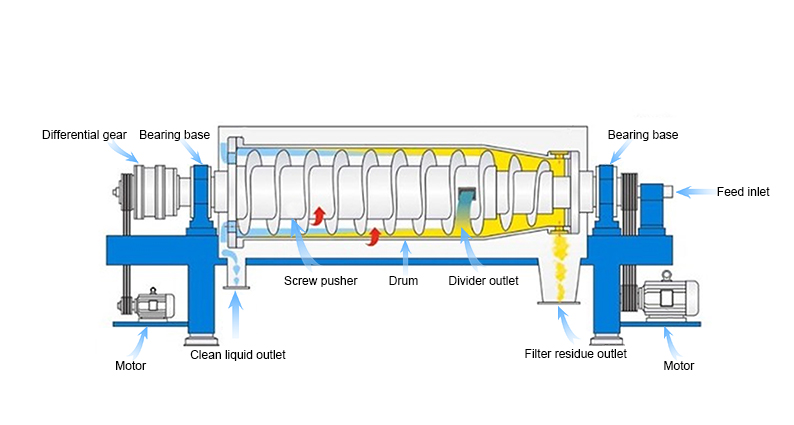

Decanter Centrifuge

The three-phase centrifuge can realize the separation of fish residue (solid phase), fish oil (light phase) and protein water (heavy phase).

The extrusion liquid (pressing liquid) of the press contains water, fish oil and fish residue, which generally account for about 70% of the raw fish. Due to the different specific gravity, the three materials can be separated by a centrifuge, but the premise is that the materials need to be heated to 85-95 °C to ensure the separation of protein water and fish oil.

Parameters

Core Parameters| Size | 3175X890X1080 |

|---|---|

| Weight | 1800 Kg |

| Max Speed | 3800 r/min |

| Drum Diameter | 355 mm |

| Drum Length | 1600 mm |

| Capacity | 3-4 m3/h |

Features

Small footprint

The extraction rate of fish oil is as high as 98%

Low fish meal fat content

Higher freshness of fish meal

Higher separation

High speed of the machine and high separation factor

Low energy consumption

The machine is driven by double motors, in which the small motor is always in the power generation state, and the electric energy generated during operation is returned to the large motor through the common DC bus; the water phase of the machine is discharged by the pump, and the kinetic energy generated by the water phase The loss is small and the overall system is more energy efficient.

Application

Working Principle

A three-phase centrifuge consists of several important components: a semi-cylindrical and semi-conical bowl, a screw conveyor of the same shape and a centripetal pump for adjusting the liquid level. The pressed liquid is pumped into the centrifuge. Under the action of huge centrifugal force, the material is divided into three layers along the drum wall. The outermost layer is solid residue, then protein water, and the innermost layer is fish oil. The solid slag is pushed to the solid slag discharge end by the screw conveyor in the center of the drum, and then mixed with the pressed cake and then enters the dryer.

The height of the fish oil layer changes with different materials. By adjusting the centripetal pump, the separation of protein water and fish oil is realized. In actual operation, it is difficult to achieve perfect separation of oil and water, so when adjusting the centrifugal pump, it will be over-adjusted to ensure the purity of a certain phase.

For example, if we want the oil to contain as little water as possible, we only need to place the liquid inlet of the centrifugal pump below the oil-water separation layer. Conversely, if we want the protein water to contain as little oil as possible, we only need to place the inlet position of the centrifugal pump above the oil-water separation layer.

Document

Get detailed specifications and parameters, Supports on-demand customization, welcome to inquire!

Related Articles

Fishmeal processing machinery is a kind ...

The fish meal dryer is composed of a she...

What are the maintenance work of waste g...