The fish meal odor problem complained by residents in a certain place this year is only a fish meal trading company's warehouse where fishmeal is stored. The surrounding air environment has been affected because the odor has not been dealt with. This has revealed that the environmental impact of the fish meal industry needs to be addressed urgently.

The fish meal processing of the fish meal factory is to use the scraps of aquatic products and some small fish and shrimp to make fish meal for feed through high-temperature steam cooking, pressing, drying, crushing and other processes. Malodorous gas is produced in many links in production, and the odor causes serious air pollution. In particular, some fishmeal production enterprises are generally small in scale, with less investment, relatively backward equipment and technology, irregular operation and management, and more obvious odor pollution.

1.The source of odor from fish meal processing

Organized emission sources: high-temperature cooking exhaust gas of wet drying furnace, drying exhaust gas of dryer;

Unorganized emission sources: raw material storage yard, waste water, waste water treatment station, raw material transfer in production, etc.

Among them, high-temperature cooking, raw material storage yard, and raw material transfer are the main sources of odor.

The known components of fish meal odor are mainly acrolein, butyric acid and valeric acid, oil degradation products, hydrogen sulfide, ammonia, and trimethylamine. The concentration of trimethylamine in the waste gas discharged during the processing of fish meal can reach 600mg/m3, hydrogen sulfide can reach 30mg/m3, and the odor intensity is 4000~10000 (fresh fish processing). Up to more than 100,000.

2. Solutions for odor removal from fish meal processing

At present, the general fishmeal odor solution technology on the market can be roughly divided into the following points:

Combustion deodorization

adsorption deodorization

chemical deodorization

dissolution deodorization

biological deodorization

Today we mainly introduce the following biological trickle filter deodorization system launched by our company.

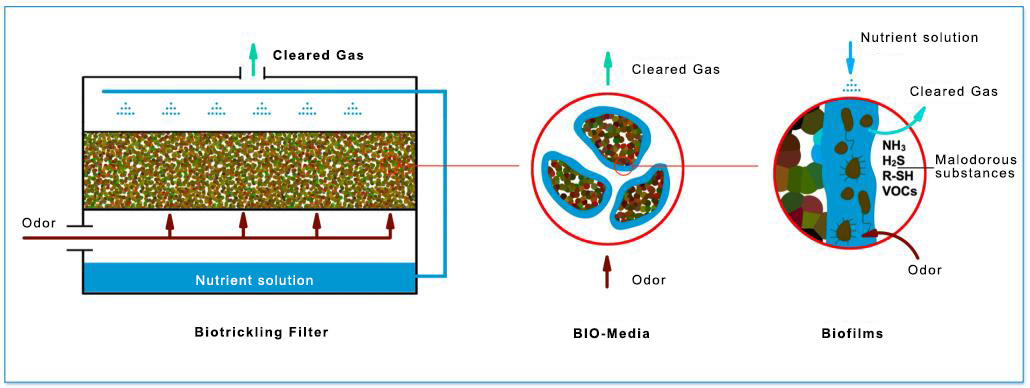

Biological trickling filtration is a type of biological filtration. The difference is that biological trickling filtration is equipped with a spray system. Compared with ordinary biological filters, biological trickling filtration can treat higher concentrations of pollutants with higher efficiency.

Through the biofilm absorption and metabolism on the filler, the pollutants in the gas are degraded into odorless and harmless small molecular substances. Moisture and other nutrients required by microorganisms are provided by a circulating trickling filter device. Through the circulation of nutrient solution, the growth environment of microorganisms is controlled. The tunability of the growth environment of microorganisms is the distinguishing feature of biological trickling filtration from other biological filtration technologies.

3. Practical application of biological trickling filtration in odor treatment of fishmeal factory

| Contents | Parameters | (200T/d fishmeal) fishmeal plant parameters |

| Height of packing layer | 1-1.5m | 1.2m |

| Area of biofilter | 1-3000m2 | 70m2 |

| Flow | 50-300,000m3/h | 10,000m3/h |

| Surface load | 5-500m3m-2h-1 | 142m3m-2h-1 |

| Void ratio | 50% | 50% |

| Operating temperature | 25-40℃ | 30-35℃ |

| pH of packing layer | 6-8 | 6-8 |

| Residence time of gas | 15-60s | 30s |

| Concentration of odor | 0.01-5gm-3/500-200,000 OUm-3 | Depends on the freshness of the fish |

| Efficiency of odor removal | 60-100% | 85-95% |

Feeds Machinery provides the design, manufacture, installation, commissioning and after-sales maintenance of a complete set of fish meal and fish oil equipment production lines, and provides customers with complete sewage and waste gas treatment solutions to achieve pollution-free fish meal industry.

Based on years of R&D and production experience of fish meal equipment production lines, Feeds Machinery has launched the Fish Meal Process (FMP), a wet-process fish meal production process, which is suitable for the production of fish meal with a raw material capacity of up to 15 tons/hour and above. The produced fish meal has better quality, high digestibility, low energy consumption and simple operation. If a complete fish meal and fish oil production and treatment system is used, the production capacity can be increased by 5% (the digestibility is increased by 3%), and at the same time, the whole process can be made pollution-free with the biological deodorization solution.