With the continuous development of the domestic fishmeal industry, the number of fishmeal factories is also gradually increasing. The rapid development of fishmeal processing industry has also brought a series of environmental problems. Some small-scale fishmeal processing factories have relatively backward equipment and processes. The operation and management are not standardized, and the odor pollution is more obvious. In recent years, environmental complaints have occurred frequently due to fishmeal processing.

The source of odor from fish meal processing

Fish meal processing is a process of high-temperature steam cooking, pressing, drying, and crushing of fish and shrimp raw materials or scraps, and then making fish meal. These processes will generate a series of sewage and waste gas that need to be treated.

The main sources of odor are:

Organized emission sources: high-temperature cooking exhaust gas of wet drying furnace, drying exhaust gas of dryer;

Unorganized emission sources: raw material storage yard, waste water, waste water treatment station, raw material transfer in production, etc.

Among them, high-temperature cooking, raw material storage yard, and raw material transfer are the main sources of odor.

Malodorous gas composition analysis

The odorous gas produced during the processing of fish meal has complex chemical components and many influencing factors. There is no comprehensive composition analysis data yet. The known components are mainly acrolein, butyric acid and valeric acid, oil degradation products, and hydrogen sulfide. , ammonia, and trimethylamine. It will even produce some toxic substances, such as hydrogen sulfide, so it is necessary to reduce emissions and control odors!

Deodorization treatment method of waste gas from fish meal processing plants

Odor characteristics of fish meal processing

Regarding the waste gas generated in the processing of fishmeal, we found that although the composition of fishmeal odor is relatively complex, it also has the following characteristics: easy to collect, low odor concentration, and good odor biochemical properties.

Fish meal processing odor control method

There are many ways to control the odor of fish meal processing:

Oxidative combustion deodorization

Odor is oxidized and catalytically burned by utilizing the reducing properties of most odorous substances. The former can sometimes recover heat, and the instability of production in small and medium-sized fish meal factories makes heat recovery more difficult; the latter can be operated at low temperature, but the catalyst is easily poisoned. , block, use less. It is characterized by high efficiency and high cost.

Adsorption and deodorization

Adsorbent activated carbon, activated clay and other odorous substances are used to adsorb odorous substances, with high deodorization efficiency and low power consumption. It is suitable for waste gas with low odor concentration and no particles, and is not suitable for fish meal production.

Chemical deodorization

Borrowing the chemical unit operation theory, it is suitable for the treatment of waste gas with high concentration of odor pollutants. The technology is mature, the operation is stable, the area is small, and the treatment efficiency is high.

Water-soluble deodorant

Dissolving odorous gas with water to remove odor is characterized by lower investment and operating costs, but the purification effect is not good, and the amount of wastewater produced is too large.

Biological deodorization

According to the characteristics of fishmeal waste gas, combined with the advantages of chemical deodorization and adsorption deodorization, the biological trickling filtration technology is especially suitable for the waste gas pollution of fishmeal processing plants, which can improve the deodorization efficiency of fishmeal processing and reduce operating costs. For the purpose of producing fish meal with complex odor components, this method is applicable.

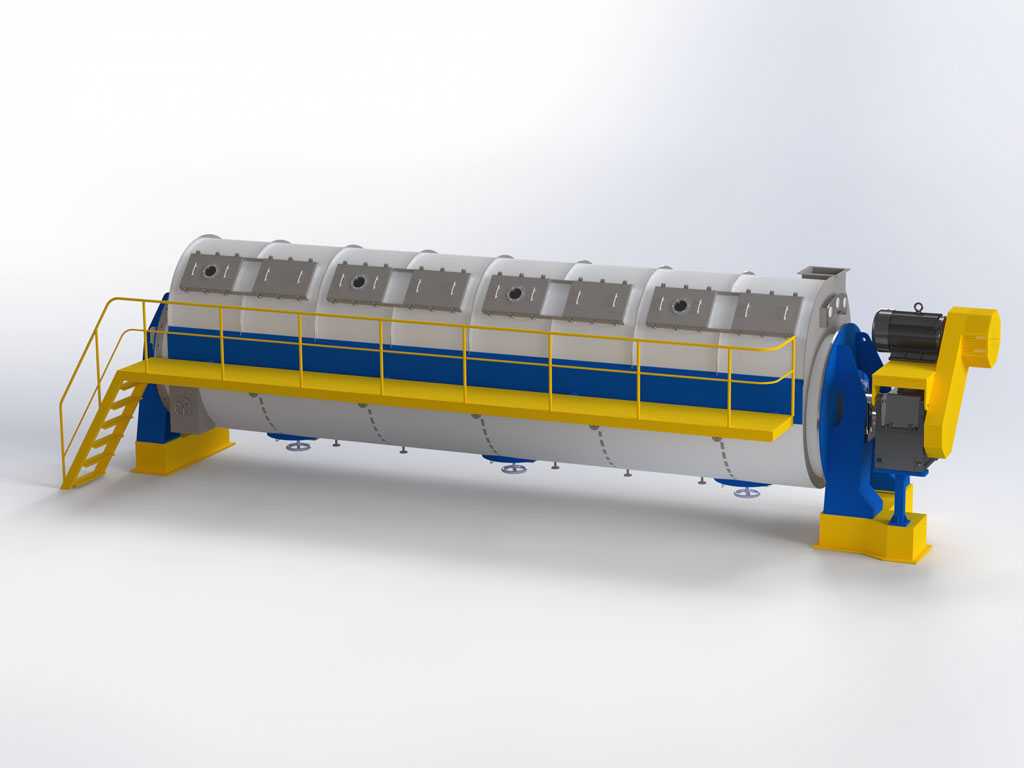

FEEDSMACHINERY provides the design, manufacture, installation,

commissioning and after-sales maintenance of a complete set of fishmeal

and fish oil production lines machine, and provides customers with

complete sewage and waste gas treatment solutions to achieve

pollution-free fishmeal industry.

Based on years of R&D and

production experience of fish meal plant production lines , FEEDSMACHINERY has launched the Fishmeal Process (FMP), a wet-process

fishmeal production process, which is suitable for the production of

fishmeal with a raw material capacity of up to 15 tons/hour and above.

The produced fishmeal has better quality, high digestibility, low energy

consumption and simple operation. If a complete fishmeal and fish oil

production and processing system is adopted, the production capacity can

be increased by 5% (the digestibility is increased by 3%), and the

whole process can be achieved without pollution.